Get This Report on Flooring

Wiki Article

The Greatest Guide To Flooring Installation

Table of ContentsSome Known Factual Statements About Flooring Installation Excitement About Hardwood FlooringAll About Laminate Flooring9 Simple Techniques For Hardwood Floor InstallationTop Guidelines Of Vinyl Flooring

These 2 parts are blended prior to application. When the resin and the hardener are incorporated, they engage in a chain reaction that produces cross-linking of the elements as it treatments. The outcome of the chemical response is a hardened, rigid plastic coating product that bonds well to most base layers.One of the other substantial advantages of polyurethane floor finishes is their treating time. Floors covered with this material can be ready for operation the following day. In comparison, epoxy finishes need a minimum of seven days to heal prior to they can be on-line. While polyurethane possesses numerous useful properties, they do have a couple of drawbacks.

Luka and his team were prompt, clean as well as very specialist. It was certainly among my higher quotes but I feel like it was greater than worth the additional cash.

9 Easy Facts About Hardwood Floor Installation Described

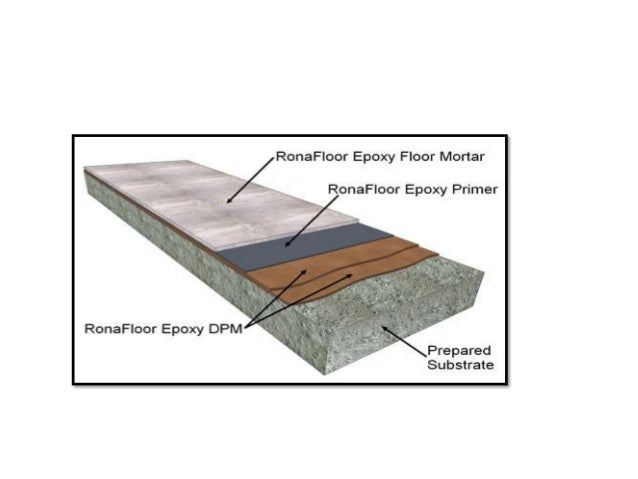

Epoxy is a high-performance concrete finish that is made up of two main parts: resins and hardeners. The material as well as hardener are blended together where a chain reaction occurs to develop a rigid material. This product is strong, resistant to degradation, bonds exceptionally well to substratums, and is cosmetically pleasing.It's important to comprehend the distinction between a high-performance industrial-strength epoxy covering item as well as a cheap epoxy paint (what you can purchase from the regional equipment store). As you proceed checking out, when we describe our systems that utilize epoxy we are referring just to the most effective quality industrial-strength epoxy items available.

To help put this right into perspective, take into consideration one more sort of flooring - hardwood flooring. Obviously, no one needs to try setting up plywood in their cooking area in place of the 'expensive' wood boards that the pro's would certainly install. That is because the outcome will certainly not function, it will not withstand, and also will most likely be dangerous and untidy.

The Single Strategy To Use For Vinyl Flooring

Epoxy floor covering consists of a Resin see it here component and also a Hardener part, much like epoxy adhesive. High top quality epoxy flooring paints are neither one component, oil based neither water based and all epoxies are not the exact same.

Positioning epoxy floor covering in the same classification as conventional garage floor paints resembles saying a Volkswagen Beetle coincides as a Ferrari because they are both automobiles. Not knowing the differences in between paints and the numerous types of epoxies will lead to you winding up with a floor that does not look right as quickly as you're done or a floor that puts on and also falls short in no time.

Not worth minority bucks you might have conserved or invested even more on with one more brand name that was substandard. An epoxy flooring finishing will stick to your garage flooring or any type of concrete flooring for that matter method much better than any kind of standard oil based, water or enamel paint, think epoxy glue type attachment vs duct tape attachment.

Top Guidelines Of Flooring Stores

A good epoxy flooring finish when cured is practically discolor evidence and cleansing it is comparable to cleansing your Teflon pan. Our epoxy layers are offered in many different shades with personalized shades readily available for bigger size floors. We additionally have decorative shade flakes that can be added into the epoxy for a granite kind appearance.We've done every kind of floor there is with every kind of item ever created so we recognize specifically what works and what does not function and also it's a reason we are the largest online epoxy floor covering vendors. Exist Different Type Of Garage Coatings? What does that suggest? It implies that with 100% solids you are getting 100% paint so that whatever you place down is what you obtain.

The part that evaporates is either solvents in the situation of solids paints or water in the instance of water based epoxy paints. If an epoxy is 50% solids it means that 50% of the covering you use will vaporize away as it dries out. The lower the portion of solids the reduced the high quality is a great guideline of thumb, with water based paints being the least expensive top quality.

We identify these as glorified concrete sealers. One Part Go Here Epoxy Coatings & Coatings That Do Not Need Floor Preparation One point we understand without a doubt is that all the one part epoxies we have actually attempted do not work. They tend to be thin, difficult to collaborate with as well as not a good idea when using shade flakes.

The Single Strategy To Use For Vinyl Flooring

In heavier flake applications the flake can actually sink down onto the concrete meaning you have little to no epoxy on the concrete. This is why we don't use color flakes with our commercial covering. The base coat is designed to be a little thinner to saturate right into the concrete as well as it works excellent wherefore it's designed for.Yearly there appears to be some new magic formula that hits the market with extravagant guarantees. Recently it has been "High Solids Epoxy" suffice. We state NO they are not, the majority of firm's epoxies do not even equivalent our guides as well as certainly their high solids epoxies are also less certified.

A primer always makes for a far better work due to the fact that it adds another layer of epoxy and also seals the flooring at the exact same time. Some flooring epoxies will certainly assert to be a primer, an epoxy and also a topcoat all in one.

Our Armor Chip Garage Epoxy package covers 575 sf. Priming is the better method to go in this instance, you get an added layer of finishing and also extended coverage of the ceramic floor tile epoxy.

Report this wiki page